This morning while I was making breakfast I found water where there wasn’t supposed to be water, on the plates. At first I thought ‘Oh I just didn’t dry them off properly‘. Nope, that was a huge wrong determination, I had a deck leak just above the plate cabinet. Second only to fire, the thing that scares the pee out of me is a leak!

Needless to say breakfast plans were abandoned and the leak search began. Luckily it was an obvious problem and easily identified. The end cap to the port side aft jib traveler track had become sun damaged, cracked, and allowed the bolt to loosen. Most sailboats are designed to shed water from bow to stern. A tsunami of water from yesterday’s cleaning got caught by the track and funneled it right down to my loose screw and into my galley cabinet.

Ok easy fix, kind of….

On my boat getting to the nut of the offending bolt requires an access panel to be removed. Unfortunately that panel only has two inches of clearance, there are eight screws holding it, and it’s upside sown. This is why boat tasks take soooo much longer to perform than pedestrian home repairs. (see image below of nut)

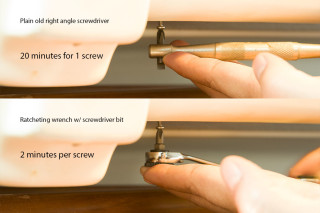

No problem, I have a right angle 4 way screwdriver for just such an occasion. The first screw I removed with this screwdriver took me almost 20 minutes and bucket load of cuss words. This tool while getting the job done requires you to get the Philips tip to mesh with the screw’s head giving you the opportunity for a measly quarter of turn. Then you have to remove the tip and reset it for another quarter turn. Did I mention I only had two inches of clearance and it was upside down.

Even Gandhi doesn’t have the patience necessary for this tedium, let alone a hungry sailor who missed his breakfast. >:/

I decided my $2 screwdriver was not cutting it and went to the hardware store to see if they had something better. Sure enough I found a small quarter inch ratcheting wrench with driver attachments for $16. Got back to the boat and removed the remaining seven screws in 15 minutes…. flat. The ratcheting mechanism removed the need to reset the tip in the screw head for each quarter turn. Zip-zip-zip-zip out came the screws.

In the end it was faster to get in the car drive to a hardware store, buy the right tool, drive back, and remove the seven remaining screws than it was to continue fumbling with the manual screwdriver. Needless to say I have tossed my old manual right angle screwdrivers. Moral of the story is the right tool for the job makes all the difference in the world not only in terms of time of repair but the patience of the captain. Get the right tool when you can, don’t try to force the wrong tool for the job.

Cheers,

Island Rambler

p.s. I will talk later about about my hydrophobia of water inside the boat. The image below shows what I’m talking about though, this is the amount of water that got into the cabin from a single loose screw (no comment about the Captain’s loose screws). If I had not found it as early as I did it could have been a nightmare down road.